The emergence of carbon fiber cues can be traced back roughly to the late 1990s and early 2000s. In a nine-ball match, American player Al Strinan represented the U.S., facing Europe’s Ronnie O’Sullivan. Strinan, having signed with a particular brand, used an all-black carbon fiber cue. At that time, commentators offered some explanation of the carbon fiber cue, essentially treating it as a complete understanding of cue materials.

In recent years, there have been dedicated carbon fiber cue shafts. Describing the hitting feel is difficult, but they are said to excel in standardization. However, their performance clearly does not surpass that of maple shafts, which is why they haven’t earned widespread trust among players. The elasticity provided by the muscle grain of high-quality maple is irreplaceable. Using carbon fiber to replicate such a complex wood structure would undoubtedly be very expensive. Additionally, carbon fiber generally lacks aesthetic appeal, making it unsuitable for high-end cues. Apart from carbon fiber, there are hardly any other synthetic or natural materials that have been used for cue construction.

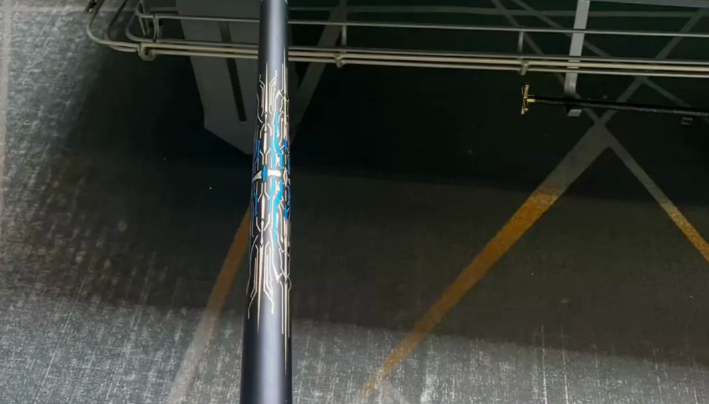

In terms of appearance, carbon fiber cues fall short compared to high-end wooden cues, making them less suitable for premium handcrafted models. Beyond carbon fiber, few other synthetic or natural materials have found practical application in cue manufacturing. The main advantages of carbon fiber cues lie in their durability and ease of maintenance. Moreover, synthetic materials can achieve the hardness that would normally require long-term air-drying of wood, giving them some advantage in break cues.

Carbon fiber cues entered the market relatively late and lack high-profile player endorsements. Most high-end handcrafted cues still rely on wood. Many players find all-carbon cues to feel too stiff, lacking the feedback of traditional wooden cues. However, each player’s preferences are different, and the feel of a cue is highly subjective, making it difficult to quantify accurately.

The pace of human advancement in material synthesis has clearly far outstripped developments in billiards technique and cue craftsmanship. Yet new materials have not yet gained widespread adoption in the cue market, mainly because neither manufacturers nor players can precisely articulate their true performance requirements. While elasticity, hardness, weight, and density are often discussed, few can clearly specify how these metrics affect the playing experience, making it difficult for material research to hit the mark.

Simply using synthetic materials to mimic high-quality woods like maple is not only costly but also inefficient. Research and data accumulation in the billiards field remain limited, with barriers from experimental testing to data analysis, which hampers the full potential of advanced technologies.

As the billiards equipment industry matures, both manufacturers and players will increasingly focus on the performance advantages that materials can bring. The application and development of technologically advanced cues are likely to accelerate gradually.